Het arrangement Aircraft Weighing Lespresentatie is gemaakt met Wikiwijs van Kennisnet. Wikiwijs is hét onderwijsplatform waar je leermiddelen zoekt, maakt en deelt.

- Auteurs

- Laatst gewijzigd

- 22-03-2022 21:13:43

- Licentie

-

Dit lesmateriaal is gepubliceerd onder de Creative Commons Naamsvermelding 3.0 Nederlands licentie. Dit houdt in dat je onder de voorwaarde van naamsvermelding vrij bent om:

- het werk te delen - te kopiëren, te verspreiden en door te geven via elk medium of bestandsformaat

- het werk te bewerken - te remixen, te veranderen en afgeleide werken te maken

- voor alle doeleinden, inclusief commerciële doeleinden.

Meer informatie over de CC Naamsvermelding 3.0 Nederland licentie.

This ELO lesson is made in cooperation with:

EMBRY-RIDDLE: Aeronautical University: Mitchell. A. Geraci

Thomas Yanus

Aircraft Maintenance & Training School: Corneel.J.P.M van Terheijden

Jaco Ponse

Rob van den Berg

Bronnen:

FAA: Aircraft Weight and Balance Handbook.

Fokker Training course Aircraft Weighing.

Video form: ATPL Training.

Aanvullende informatie over dit lesmateriaal

Van dit lesmateriaal is de volgende aanvullende informatie beschikbaar:

- Toelichting

- Introductie les voor het wegen van een vliegtuig.

- Leerniveau

- Volwasseneneducatie, Niveau 4; MBO, Niveau 4: Middenkaderopleiding;

- Eindgebruiker

- leerling/student

- Moeilijkheidsgraad

- moeilijk

- Studiebelasting

- 4 uur 0 minuten

- Trefwoorden

- aircraft weighing, centre of gravity, gewicht, vliegtuig wegen, vliegtuiggewicht, vliegtuigtechniek, weegschaal, wegen, weight, weight and balance

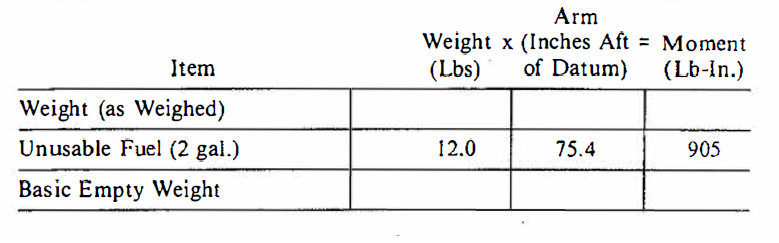

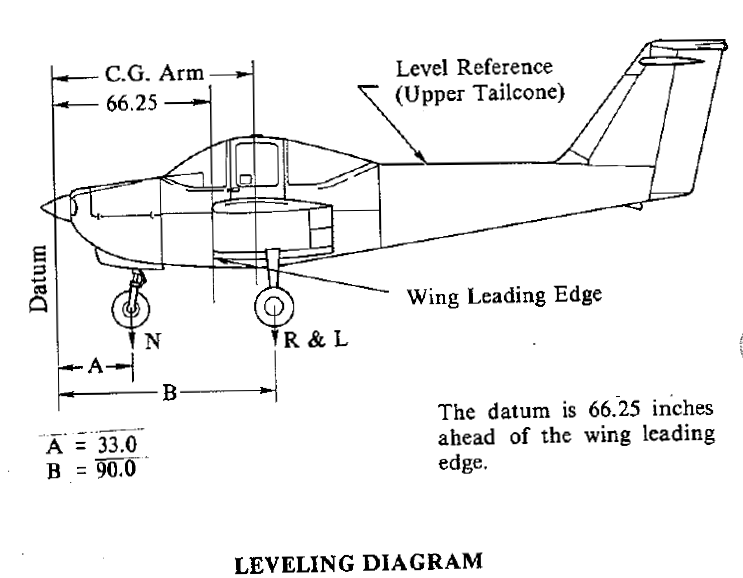

The empty weight center of gravity (as weighed including optional equipment, full oil and operating fluids) can be determined by the followingformula:

The empty weight center of gravity (as weighed including optional equipment, full oil and operating fluids) can be determined by the followingformula: